Industrial Air Products

Impeccable service, high quality standards, continued growth & prosperity

| Bohn Web Design Copyright © 2016 to Present. All rights reserved. | Technical Assistance: Lynne@BohnWebDesign.com |

ABOUT IAP, INC.

Providing quality fan equipment with dependable

service

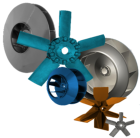

Industrial Air Products, Inc. (IAP) was founded on the

idea of designing and manufacturing blowers and fans

according to customer’s unique requirements.

Focusing on a customer-driven approach is a novel

way to do business in the industrial arena.

Since 1974, IAP has supplied markets with quality

industrial air moving equipment. From design to

fabrication and delivery with ongoing service, IAP is a

complete resource for fans, blowers, and dampers.

IAP has grown and changed over the years as our

customers' needs have changed. One thing that has

remained constant is that IAP builds the highest quality

industrial fan equipment on the market.

IAP maintains a competitive edge with prompt order

fulfillment, technologically superior engineering,

excellent customer relations, custom design

capabilities, and quick turnaround time on rush orders.

Innovative fan sizing and pricing software assist IAP's

sales group's efficiency and thoroughness.

IAP has earned an international reputation for trouble-

free performance and consistent quality of its custom

and standard industrial fans and blowers.

IAP’s team of engineers and master craftsmen ensures

the equipment meets your every expectation, and a

network of more than 50 sales offices in the United

States, Canada, and Mexico make it possible to assist

our customers locally. IAP has experienced sales

engineers throughout the world.

We're committed to providing impeccable service.

Friendly, knowledgeable, and ready to go the extra

mile, our staff members understand the customer

always comes first.

We're dedicated to maintaining high quality standards.

Personal responsibility, modern facilities, utilization of

current technologies, and rigorous checking assure

high-quality products with lasting value.

We're focused on continued growth and prosperity.

By building the very best products, our customers,

staff, and community all prosper. It is a vision that

extends beyond dollars to a way of working and living

that brings pride to us all.

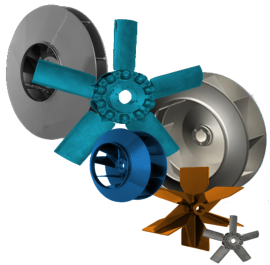

ENGINEERING

IAP engineering solves customer problems by

designing fans and blowers that provide required

performance and longevity. Our engineering team is

readily able and willing to work with customers

regarding their applications.

AMCA Registered Air Performance Test Laboratory

The IAP laboratory is utilized for product

development, AMCA check tests and customer

witness tests.

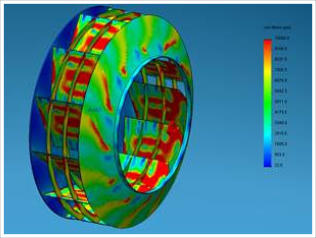

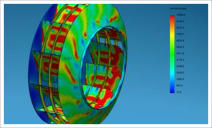

Finite Element Analysis (FEA)

IAP uses stress analysis software to determine

maximum allowable stress for new products and

extreme applications.

Computer-aided Design

IAP utilizes CADKEY and AutoCAD design

software to generate electronic scale drawings.

MANUFACTURING

IAP’s 65,000 square foot facility builds each fan to our

rigid standards and your exact specifications. IAP’s

Phillips, WI facility employs approximately 60 factory

and 15 office personnel. Our entire company is

housed in one facility with the exception of our sales

office in St. Paul, MN. Having our manufacturing and

engineering personnel in one building assures that our

product is built with the highest quality possible.

OUR HISTORY

IAP Inc. is founded by Bob Theis. Bob was a former fan

manufacturer's representative and saw a requirement for

custom, heavy duty industrial fans that were not being

offered by his principal. Having a background in fan

design prior to becoming a manufacturer's rep, Bob was

able to parlay his talents and experiences and formed

Industrial Air Products (IAP), an industrial manufacturer of

heavy duty customized fans.

Throughout 1974 and 1975, Bob served as Industrial Air

Products’ sole employee. He engineered, marketed, and

sold all of IAP's blowers. Construction of the fans was

contracted out to fabrication shops.

IAP contracts construction for a 60' x 40' manufacturing

facility on a former potato farm in Phillips, Wisconsin.

By this time, IAP has seven employees. IAP secures a

contract for a representative office in Michigan. This

representative office is IAP's first manufacturer's

representative.

IAP continues to add representative offices and establishes

a national presence with the addition of its first National

Sales Manager. This was the first major change in

direction for IAP. The change had a purpose of

reorganizing the company from a regional job shop to a

national supplier of industrial fan equipment. IAP is

unanimously approved for AMCA membership.

IAP conducts its first national sales meeting in Wausau, WI.

IAP begins to utilize computerized CAD as its primary

design tool. IAP expands its Phillips, WI facility for a 3rd

time to over 40,000 square feet of capacity.

IAP receives AMCA registration of its fan performance test

chamber. IAP hosts its second national sales meeting later

that same year in Wausau, WI.

IAP engineering becomes one of the first fan

manufacturing engineering departments to utilize Finite

Element Analysis software. The software has since been

updated and remains a current tool for the design and

development of blower impellers.

IAP receives AMCA license for the backwardly-inclined fan

line.

IAP releases one of the first fan selection software

programs to the market. IAP Hosts its third national sales

meeting on the shores of Lake Superior in beautiful

Ashland, WI.

IAP expands marketing and is heavily present at industry

trade shows and in print.

IAP hosts its fourth national sales meeting, once again in

Ashland, WI. IAP releases a second major revision to its

fan selection software program, FanPro, which is now fully

Windows-driven.

IAP adds sales offices in St. Paul, MN.

IAP Hosts its fifth national sales meeting, in Cable, WI at

the world famous Telemark Lodge. IAP releases its fan

drawing software, Fan Wizard, and fan pricing software,

Fan Value.

IAP is awarded a major contract for tunnel ventilation, one

of the largest projects of its kind to date.

IAP is awarded a major contract for wastewater treatment

odor control equipment in Los Angeles County. Besides

two 1250 hp fans, the project scope includes a number of

other fans, motors, VFDs, silencers, oil circulations

systems, and numerous other ancillary equipment.

IAP expands its Phillips, WI facility to 62,000 square feet

capacity. IAP hosts its sixth national sales meeting,

returning to Wausau, WI for the meeting. Major

improvements to FanPro (selection software) are released

and include the ability to select multiple fans and save

them to a project schedule.

While continuing to build its North American sales force,

IAP secures more and more sales beyond North America

with significant exports to Europe, Australia, Africa, and

the Middle East.

The United States lost one-third of all manufacturing jobs

in the first 10 years of the 2000s and manufacturing sees

a significant downturn in available work in the last two

years of the decade. IAP is not impervious; however,

continues to provide quality equipment and service,

sustains through the great recession, and is back to

previous employment levels by the end of 2011.

The number of IAP full time employees is at an all-time

high and sales are at record levels.

IAP expands its Phillips, WI factory to 65,000 square feet,

expanding inventory by 200% as well as adding a

sheltered loading dock and cold storage area.

Founder Bob Theis passes away. IAP continues to grow,

securing major contracts in the steel and dairy industries

this same year. They are both the type of fan projects that

require adaptive custom engineering alterations to

standard fans; exactly the type of work that Bob founded

IAP on and would proudly tout.

IAP adds a second high definition 30' plasma burn table.

This addition improves overall manufacturing efficiency

while maintaining the high quality standards for which IAP

is known.

‘83

‘74

‘75

‘76

‘79

‘84

‘86

‘88

‘89

‘90

‘92

‘95

‘97

‘00

‘02

‘03

‘05

‘06

‘07

‘11

‘12

‘13

‘15

‘16

Industrial Air Products

Impeccable service, high quality

standards, continued growth & prosperity

ABOUT IAP, INC.

Providing quality fan equipment with dependable service

Industrial Air Products, Inc. (IAP) was founded on the

idea of designing and manufacturing blowers and fans

according to customer’s unique requirements. Focusing

on a customer-driven approach is a novel way to do

business in the industrial arena.

Since 1974, IAP has supplied markets with quality

industrial air moving equipment. From design to

fabrication and delivery with ongoing service, IAP is a

complete resource for fans, blowers, and dampers.

IAP has grown and changed over the years as our

customers' needs have changed. One thing that has

remained constant is that IAP builds the highest quality

industrial fan equipment on the market.

IAP maintains a competitive edge with prompt order

fulfillment, technologically superior engineering,

excellent customer relations, custom design capabilities,

and quick turnaround time on rush orders. Innovative

fan sizing and pricing software assist IAP's sales group's

efficiency and thoroughness.

IAP has earned an international reputation for trouble-

free performance and consistent quality of its custom

and standard industrial fans and blowers.

IAP’s team of engineers and master craftsmen ensures

the equipment meets your every expectation, and a

network of more than 50 sales offices in the United

States, Canada, and Mexico make it possible to assist

our customers locally. IAP has experienced sales

engineers throughout the world.

We're committed to providing impeccable service.

Friendly, knowledgeable, and ready to go the extra mile,

our staff members understand the customer always

comes first.

We're dedicated to maintaining high quality standards.

Personal responsibility, modern facilities, utilization of

current technologies, and rigorous checking assure

high-quality products with lasting value.

We're focused on continued growth and prosperity.

By building the very best products, our customers, staff,

and community all prosper. It is a vision that extends

beyond dollars to a way of working and living that

brings pride to us all.

ENGINEERING

IAP engineering solves customer problems by designing

fans and blowers that provide required performance and

longevity. Our engineering team is readily able and

willing to work with customers regarding their

applications.

AMCA Registered Air Performance Test Laboratory

The IAP laboratory is utilized for product

development, AMCA check tests and customer

witness tests.

Finite Element Analysis (FEA)

IAP uses stress analysis software to determine

maximum allowable stress for new products and

extreme applications.

Computer-aided Design

IAP utilizes CADKEY and AutoCAD design software

to generate electronic scale drawings.

MANUFACTURING

IAP’s 65,000 square foot facility builds each fan to our

rigid standards and your exact specifications. IAP’s

Phillips, WI facility employs approximately 60 factory

and 15 office personnel. Our entire company is housed

in one facility with the exception of our sales office in St.

Paul, MN. Having our manufacturing and engineering

personnel in one building assures that our product is

built with the highest quality possible.

OUR HISTORY

IAP Inc. is founded by Bob Theis. Bob was a former fan

manufacturer's representative and saw a requirement for

custom, heavy duty industrial fans that were not being

offered by his principal. Having a background in fan

design prior to becoming a manufacturer's rep, Bob was

able to parlay his talents and experiences and formed

Industrial Air Products (IAP), an industrial manufacturer of

heavy duty customized fans.

Throughout 1974 and 1975, Bob served as Industrial Air

Products’ sole employee. He engineered, marketed, and

sold all of IAP's blowers. Construction of the fans was

contracted out to fabrication shops.

IAP contracts construction for a 60' x 40' manufacturing

facility on a former potato farm in Phillips, Wisconsin.

By this time, IAP has seven employees. IAP secures a

contract for a representative office in Michigan. This

representative office is IAP's first manufacturer's

representative.

IAP continues to add representative offices and establishes

a national presence with the addition of its first National

Sales Manager. This was the first major change in

direction for IAP. The change had a purpose of

reorganizing the company from a regional job shop to a

national supplier of industrial fan equipment. IAP is

unanimously approved for AMCA membership.

IAP conducts its first national sales meeting in Wausau, WI.

IAP begins to utilize computerized CAD as its primary

design tool. IAP expands its Phillips, WI facility for a 3rd

time to over 40,000 square feet of capacity.

IAP receives AMCA registration of its fan performance test

chamber. IAP hosts its second national sales meeting later

that same year in Wausau, WI.

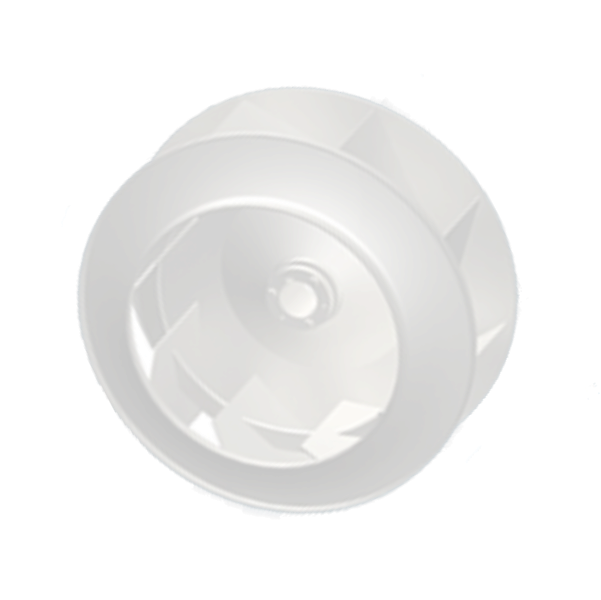

IAP engineering becomes one of the first fan

manufacturing engineering departments to utilize Finite

Element Analysis software. The software has since been

updated and remains a current tool for the design and

development of blower impellers.

IAP receives AMCA license for the backwardly-inclined fan

line.

IAP releases one of the first fan selection software

programs to the market. IAP Hosts its third national sales

meeting on the shores of Lake Superior in beautiful

Ashland, WI.

IAP expands marketing and is heavily present at industry

trade shows and in print.

IAP hosts its fourth national sales meeting, once again in

Ashland, WI. IAP releases a second major revision to its

fan selection software program, FanPro, which is now fully

Windows-driven.

IAP adds sales offices in St. Paul, MN.

IAP Hosts its fifth national sales meeting, in Cable, WI at

the world famous Telemark Lodge. IAP releases its fan

drawing software, Fan Wizard, and fan pricing software,

Fan Value.

IAP is awarded a major contract for tunnel ventilation, one

of the largest projects of its kind to date.

IAP is awarded a major contract for wastewater treatment

odor control equipment in Los Angeles County. Besides

two 1250 hp fans, the project scope includes a number of

other fans, motors, VFDs, silencers, oil circulations

systems, and numerous other ancillary equipment.

IAP expands its Phillips, WI facility to 62,000 square feet

capacity. IAP hosts its sixth national sales meeting,

returning to Wausau, WI for the meeting. Major

improvements to FanPro (selection software) are released

and include the ability to select multiple fans and save

them to a project schedule.

While continuing to build its North American sales force,

IAP secures more and more sales beyond North America

with significant exports to Europe, Australia, Africa, and

the Middle East.

The United States lost one-third of all manufacturing jobs

in the first 10 years of the 2000s and manufacturing sees

a significant downturn in available work in the last two

years of the decade. IAP is not impervious; however,

continues to provide quality equipment and service,

sustains through the great recession, and is back to

previous employment levels by the end of 2011.

The number of IAP full time employees is at an all-time

high and sales are at record levels.

IAP expands its Phillips, WI factory to 65,000 square feet,

expanding inventory by 200% as well as adding a

sheltered loading dock and cold storage area.

Founder Bob Theis passes away. IAP continues to grow,

securing major contracts in the steel and dairy industries

this same year. They are both the type of fan projects that

require adaptive custom engineering alterations to

standard fans; exactly the type of work that Bob founded

IAP on and would proudly tout.

IAP adds a second high definition 30' plasma burn table.

This addition improves overall manufacturing efficiency

while maintaining the high quality standards for which IAP

is known.

‘83

‘74

‘75

‘76

‘79

‘84

‘86

‘88

‘89

‘90

‘92

‘95

‘97

‘00

‘02

‘03

‘05

‘06

‘07

‘11

|Bohn Web Design Copyright © 2016 to Present.

All rights reserved. |

|Technical Assistance: Lynne@BohnWebDesign.com |

‘12

‘13

‘15

‘16